Expertise

We are injection moulded experts with more than 50 years’ experience in developing reusable packaging. We translate customer needs into optimized packaging designs utilising the latest techniques and state-of the-art design software.

Technical Development

Based on an idea and in close consultation we develop the most suitable solution to the smallest detail. Following a complete geometrical definition of the product, we proceed with calculations, simulations and adjustments.

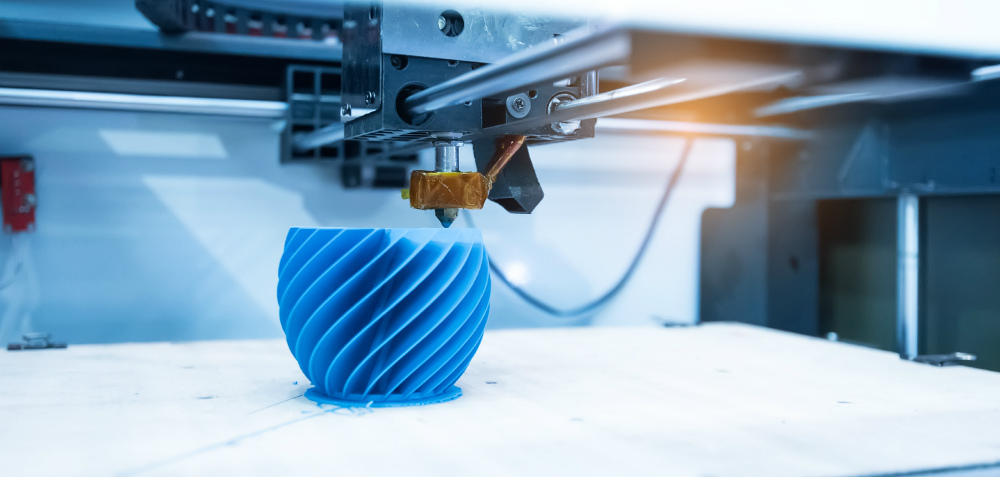

3D Printing of Prototypes

With our high-quality 3D printer, we can offer our customers prototypes of the product in a very short time frame. 3D printing technology considerably reduces our production lead-time during the development stage and it allows the design of a broad range of prototypes.

Quality Testing

DW Reusables has its own test centre. Based on years of experience, a series of quality tests have been assembled to guarantee the highest levels in quality, performance and a long-life cycle of all reusable plastic packaging.

Development of Moulds

To design a mould we start with the final approved design of the end product. On the basis of that design our technical designer creates a DFM design (Design For Manufacturing). This design guarantees that the product will comply with our quality standards.

New Product Development

The starting point for a successful new product is understanding the customers’ needs. We can start with an idea from scratch, or further develop a concept. Our customers can join workshops to reach the perfect sustainable solution.