Expanded Polypropylene

Expanded polypropylene (EPP) is a recyclable closed-cell moulded foam with an impressive set of properties that you would struggle to find in another material. After expansion EPP beads are fused into simple blocks for CNC prototyping or moulded into complicated shapes inside a steam chest.

Density range

20 – 250 g/l

Trade Names

ARPRO®®,

Key Benefits

100% Recyclable

Fully recyclable. Recycled material grades containing granulated end-of-life parts are available

Strength

Durable with high strength to weight ratio

Impact Absorption

Excellent resilience and cushioning qualities, EPP reforms to its original shape after an impact

Thermal Insulation

Outstanding thermal insulation for both hot and cold applications

Lightweight

Generates weight saving in components leading to fuel efficiencies across many modes of transport

Sound Deadening

Can dampen absorb or block sound. Porous EPP can provide enhanced acoustic insulation

Our Products

Automotive Components

Automotive cushioning components, are amongst the most important safety innovations made by the automotive industry.

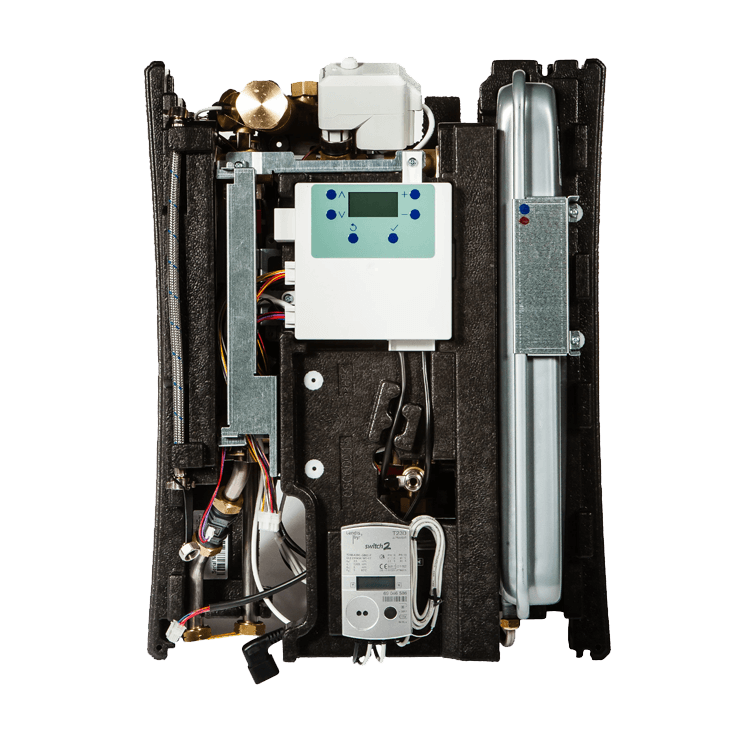

Heating Systems

HVAC system manufacturers incorporate EPP into their product designs for enhanced thermal and acoustic insulation...

UAV’s and Drones

Weight saving is vital to developing a high-performance drone or fixed wing UAV. EPP is...

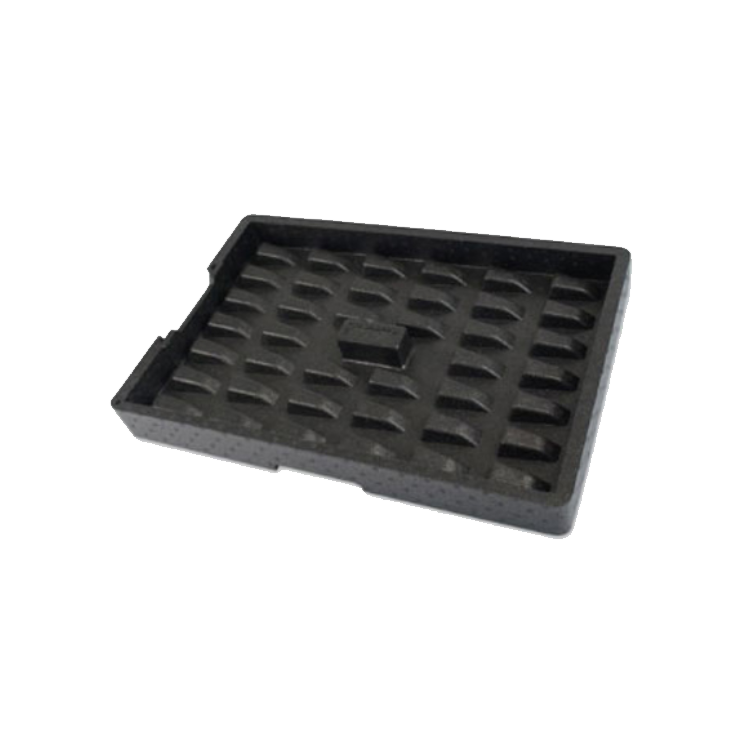

Returnable Packaging

Used extensively throughout the automotive industry, reusable dunnage trays benefit from the exceptional impact protection...

Add a splash of colour

Not everything is black and white, it’s pink, green, orange and blue too! Raw material can be pre-coloured or pigments introduced during the expansion process without any adverse effects on the performance or properties of the moulded product.

Consider injecting EPP and EPS parts with some colour for branding, product identification or to simply improve the final aesthetic and visual appeal.

How can we help you?

Contact us

Ready to discover your sustainable solution?