Worldwide Dispensers™

The global leader in creative dispensing solutions for more than 50 years

High quality

solutions for your

bottom line

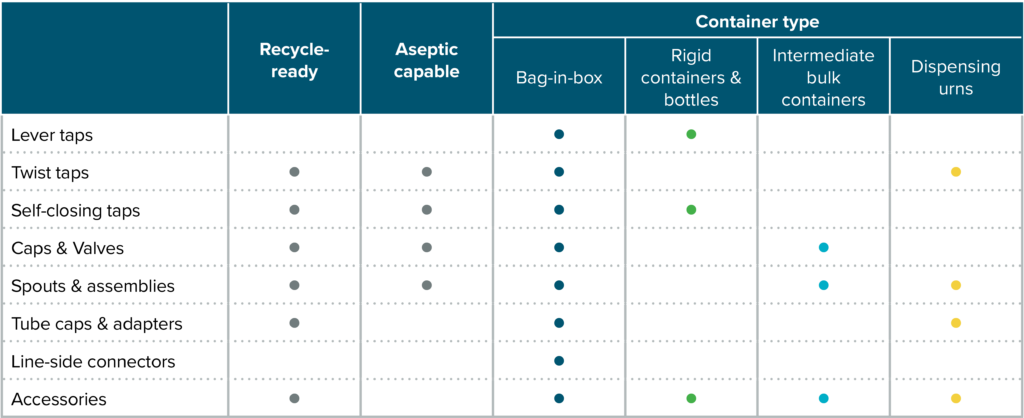

Worldwide Dispensers™ is a leading supplier of high-quality, precision-molded taps and fitments to the world’s largest consumer, biopharmaceutical and industrial brands. We manufacture a variety of closures and complementary connectors, spouts (glands) and adapters for flexible and rigid containers.

With operations spanning North America, Europe and Australasia, and a network of agents and distributors around the world, we are able to design and manufacture components in-house to quickly bring our customers the custom and standard solutions they need.

Creative dispensing

solutions

Self-closing Taps

Front push, top push and top pull self-closing taps for single-handed dispensing, featuring excellent oxygen…

Lever Taps

Easy-action dispensing taps for bag-in-box and a variety of rigid containers that offer the ability…

Twist Taps

Top-twist taps designed for continuous dispensing with a precision valve shut off feature for no…

Fitments

Our fitments portfolio includes a full range of caps, glands, tubes and connectors for all…

Let’s

connect

From greater sustainability to higher performance, we’re here to deliver what your business needs most.