Returnable Packaging

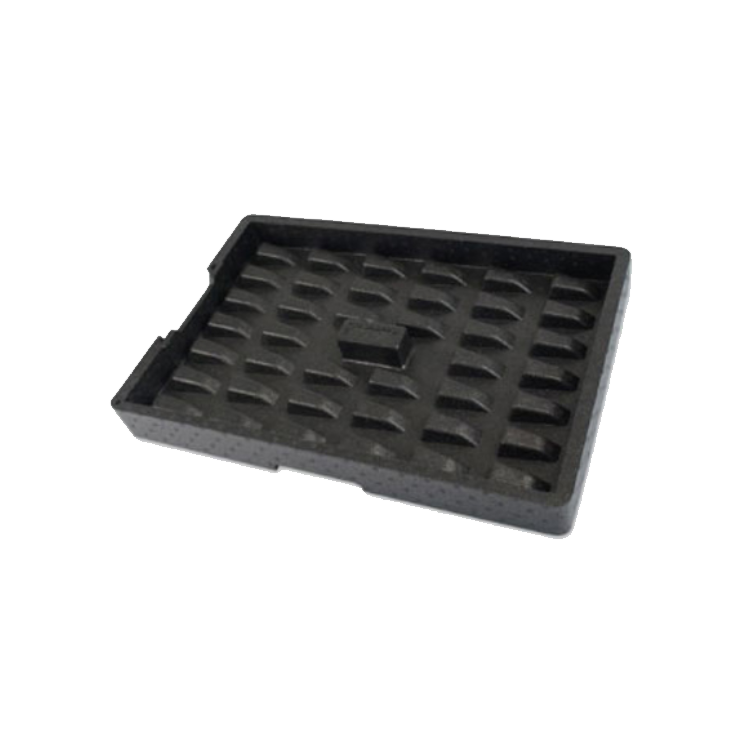

Moulded foam dunnage, most commonly black expanded polypropylene (EPP) is used extensively within the returnable packaging and automotive industry. Material handling fulfils the crucial role of ensuring the protection of high value products and parts in transit throughout the entire supply chain from manufacturing to the production line.

Material Properties

Multi Impact Protection

Resilient and recoverable material

Chemically Inert

Unaffected by contact with oil, grease, petroleum and most chemicals

100% Recyclable

Fully end of life recyclable

Industry Application

The Breakdown

Returnable Transit Packaging that improves protection and reduces damage

Used extensively throughout the automotive industry, reusable dunnage trays benefit from the exceptional impact protection properties of EPP helping reduce supply line damages.

Related Products

Automotive Components

Automotive cushioning components, are amongst the most important safety innovations made by the automotive industry.

Material Handling Systems

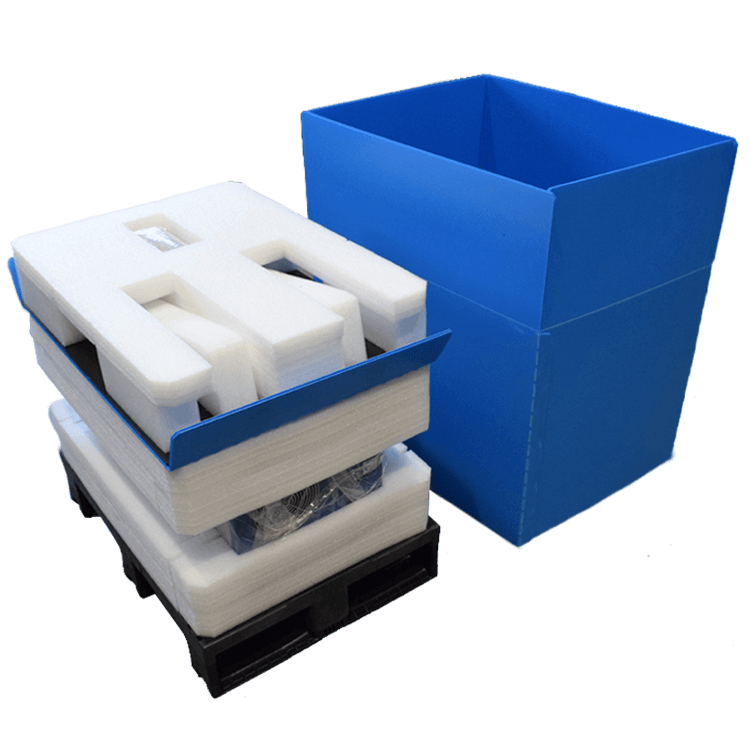

Transit packaging solutions utilise a multi material-neutral approach to develop material handling systems.

How can we help you?

Contact us

Ready to discover your sustainable solution?