Excellent Thermal Insulation

Helps to prevent and minimise heat loss

The structural strength, thermal insulation and lightweight nature of EPS and EPP has given rise to the number of applications in the Heating, Ventilation, Air-Conditioning and Refrigeration (HVAC) industry.

Moulding parts for the HVAC industry since the early 1990’s, Engineered Foam Products has obtained a wealth of knowledge and experience and now moulds over 45 air conditioning components for one customer alone.

Offering outstanding thermal properties, HVAC components manufactured from expanded foam facilitate the efficient operation of the finished product. For heat exchangers and ducting it is also important that parts seal well so air flows cannot escape or mix until required.

Working closely with customers and tool makers we ensure that the strict tolerances demanded by the industry are met. Our moulding experience and quality processes help to ensure HVAC units pass tough UK and European testing, demonstrating compliance with tests to determine efficiency and high standards for sustainable living and the environment.

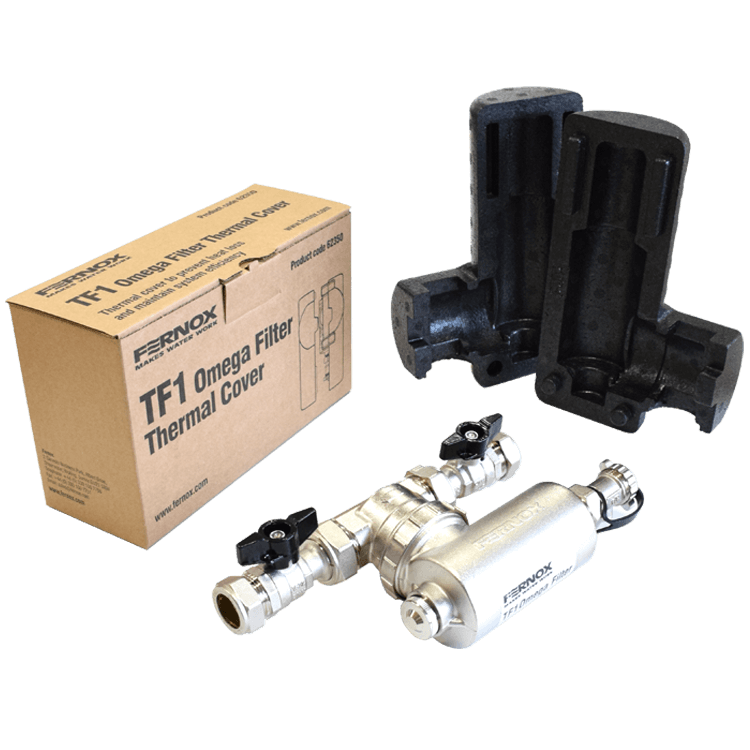

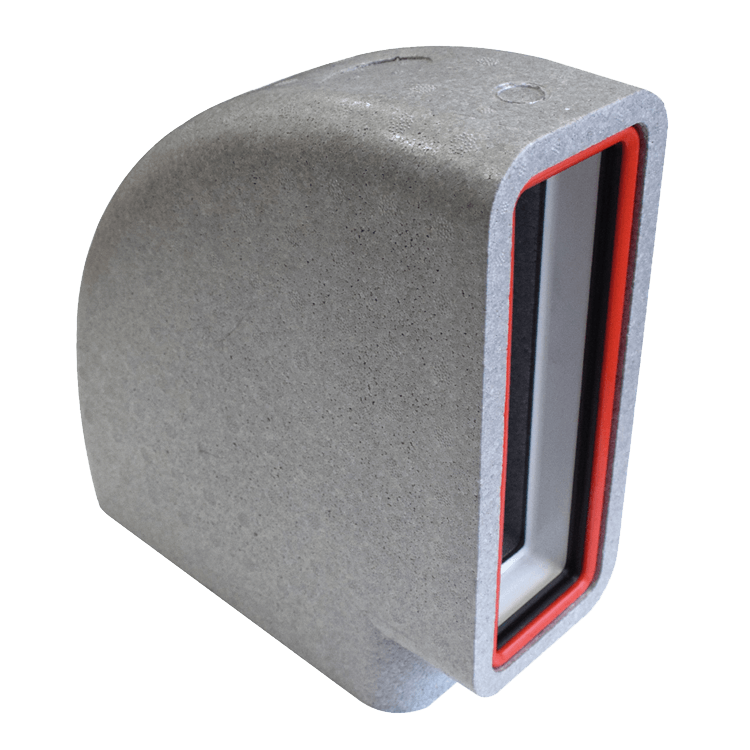

A thermal housing or jacket helps prevent heat loss and bring efficiencies to applications that revolve around maintaining stable temperatures.

Details

Lightweight expanded polystyrene (EPS) used for HVAC ducting is a durable solution preventing heat loss and speeds up HVAC system install.

Details

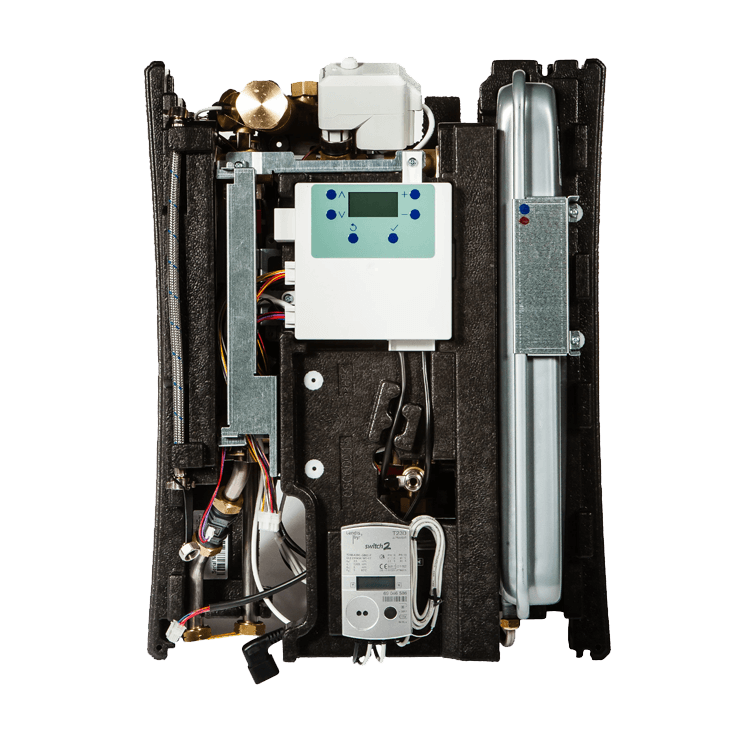

HVAC system manufacturers incorporate EPP into their product designs for enhanced thermal and acoustic insulation properties for all sorts of heating, ventilation ...

DetailsAdvanced material for next generation HVAC applications

HVAC components are now typically manufactured in medium to high density EPP material grades, replacing older and heavier metal housings we have been use to in the past. EPP housings are now mainstream becoming an essential part of improving efficient air circulation around our homes, helping to improve energy performance as we strive for the perfect temperature and air quality.

Helps to prevent and minimise heat loss

Reduces weight of components and eases handling and installation

High strength to weight ratio and durability

Can dampen absorb or block sound, Porous EPP can provide enhanced acoustic insulation

Excellent resilience and cushioning qualities, EPP reforms to its original shape after an impact.

100% recyclable and available in recycled grades containing granulated end of life parts.

Ready to discover your sustainable solution?