Energy Absorption

Excellent resilience and cushioning qualities, EPP reforms to its original shape after an impact.

Expanded Polypropylene (EPP) offers superb impact absorption performance to improve road safety for drivers, passengers and pedestrians.

Our experience manufacturing automotive foam components spans back to the late nineties when we won work to manufacture 4 side impact pieces for the door panels of the new shape Mini. We now have a dedicated, IATF 16949 accredited automotive manufacturing plant based in Spennymoor Co.Durham supplying returnable material handling dunnage and millions of component parts.

Side Impact Protection (SIPs) and Bumper Cores in moulded black EPP are a key component for making the cars we drive today ...

Details

Expanded foam assists energy management in vehicles which is a major contributor towards passenger safety.

Details

Front and rear bumper cores made from Expanded Polypropylene boast an unrivalled energy absorption and exceptional performance.

Details

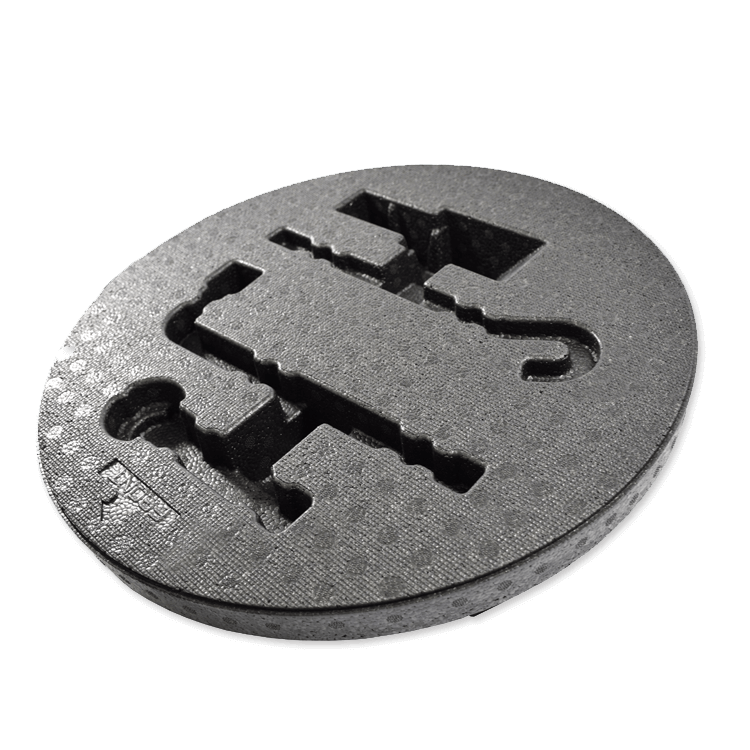

EPP (Expanded Polypropylene) is the ideal for boot fillers and tool pods/trays within the automotive industry due to the durability and lightweight ...

Details

Automotive cushioning components, are amongst the most important safety innovations made by the automotive industry.

Details

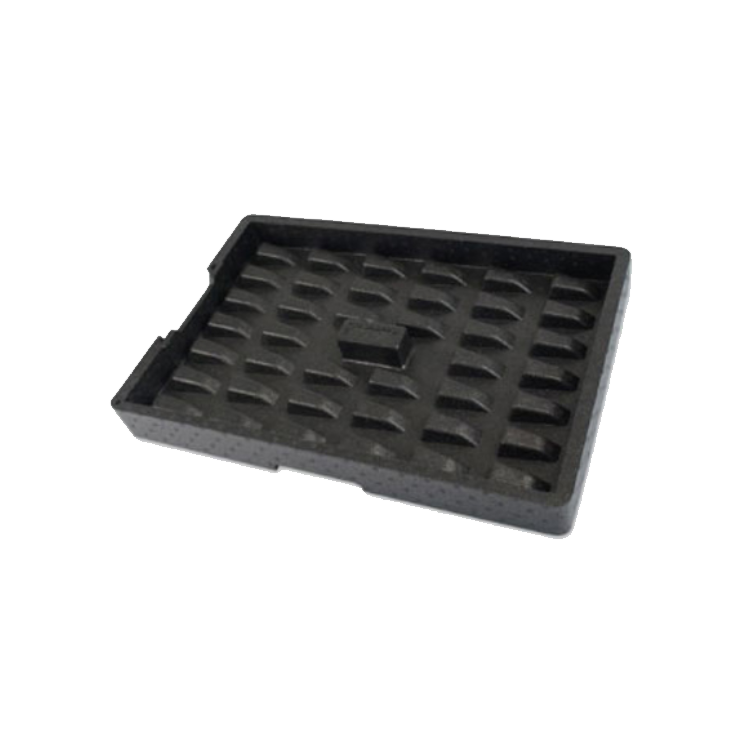

Used extensively throughout the automotive industry, reusable dunnage trays benefit from the exceptional impact protection properties of EPP helping reduce supply line ...

DetailsMoulding safer vehicles one part at a time

An important safety benefit of EPP is how it holds up to repeated impacts having the ability to rebound to its original shape. The EPP parts we manufacture are always there silently and safely ready to protect you day in day out should an accident occur. We manufacture numerous components that make up today’s modern vehicles (be it cars, vans, buses or another mode of transport).

Excellent resilience and cushioning qualities, EPP reforms to its original shape after an impact.

Outstanding thermal insulation for both hot and cold applications

Huge weight reduction potential which translates to impressive fuel efficiencies for any mode of transport.

Recoverable material that bounces back, capable of taking multiple impacts without damage.

Can dampen absorb or block sound, Porous EPP can provide enhanced acoustic insulation

100% recyclable and available in recycled grades containing granulated end of life parts.

Ready to discover your sustainable solution?